Production Solutions Engineer, Tooling Engineer

- On-site

- Palo Alto, California, United States

- Manufacturing and Production

Job description

Target start date: Immediately. Relocation provided. (Please kindly send your resume in English.)

Since its founding in 2015, 1X has been at the forefront of developing advanced humanoid robots designed for household use. Our mission is to create an abundant supply of labor via safe, intelligent humanoids.

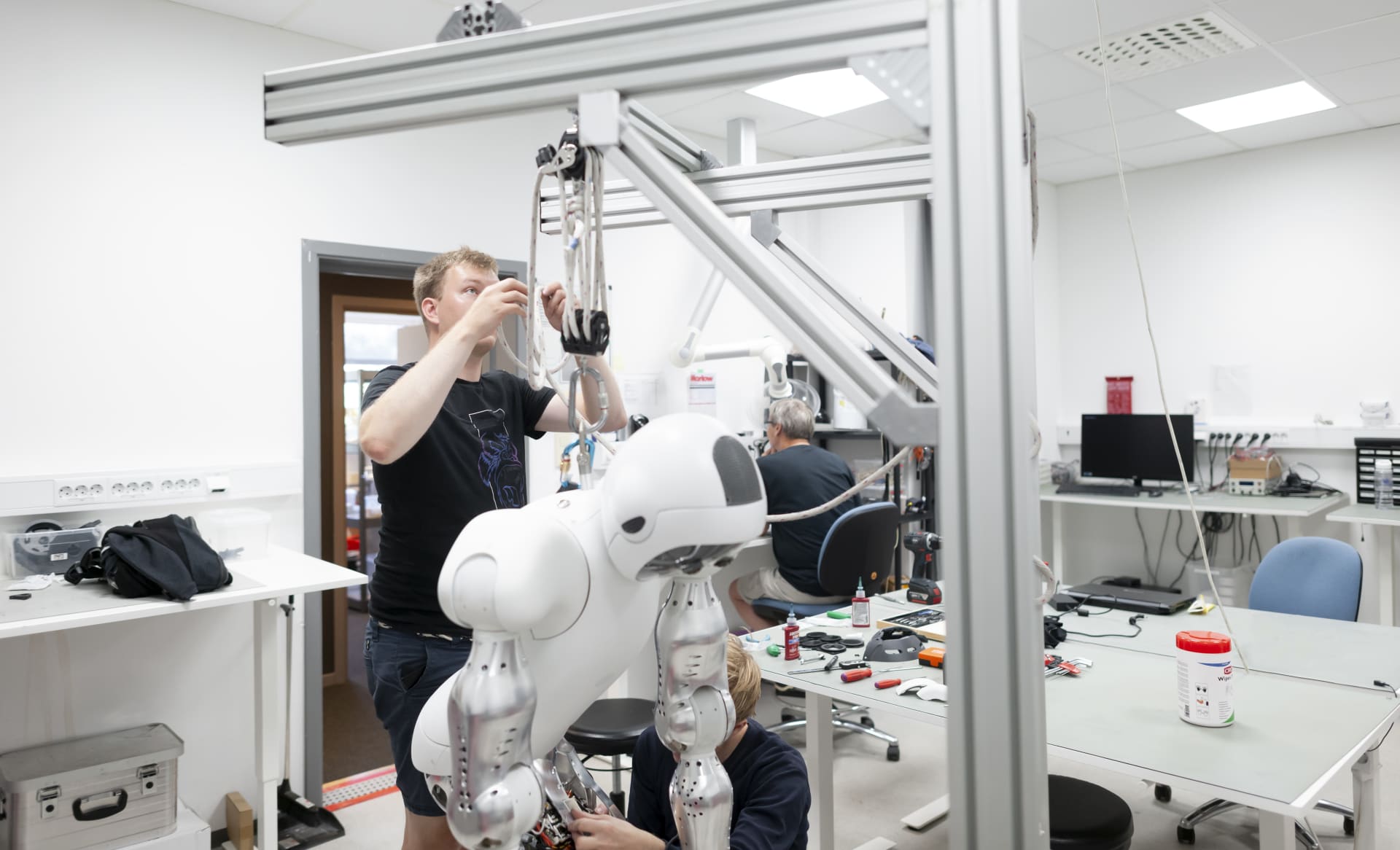

We strive for excellence in all we do, solving some of the hardest problems in robotics with the world’s most talented individuals. Every part of our robots is designed and produced in-house—from motor coils to AI—reflecting our vertically integrated approach. At 1X, you’ll own real projects, be recognized for your achievements, and rewarded based on merit.

We believe the best work is done when collaborating and therefore require in-person presence in our office locations.

As we scale from research and development to full-scale manufacturing, we are looking for a Production Solutions Engineer (Tooling Engineer) to join our internal Production Engineering team. In this role, you will be responsible for designing and commissioning jigs, fixtures, to streamline both manual and automated assembly processes (and potentially also supporting production test stations) for our next-generation bipedal humanoid robots. You will collaborate closely with cross-functional teams to scale production from prototype development to high-volume manufacturing. The ideal candidate will have a strong background in Mechanical Design, Manufacturing or Industrial Engineering, experience in tooling and fixture design, proficiency with industrial automation systems, and hands-on experience in commissioning equipment as well. A solid understanding of GD&T and design for manufacturing principles (Design for Assembly, Design for Cost, Design for Quality...) are essential, along with a proactive, problem-solving attitude.

Why this job is exciting

Every day is different! You will get to...

Define how humanoid robots and their components are assembled in a reliable and repeatable way, using cutting-edge tooling and automation solutions developed by you

Be part of a pioneering industry and help shape the future of humanoid robot production

Gain hands-on experience with state-of-the-art technology, expanding your technical skills and innovation capacity

Thrive in an inclusive, supportive, and globally diverse culture

Within one month, you will…

Familiarize yourself with our production processes, methodologies, and tooling needs

Get up to speed with our humanoid platform (NEO) and the roadmap for scaling its assembly process

Gain hands-on experience by working on the development and testing of a prototype jig or fixture

Within three months, you will…

Be self-sufficient in leading the design and commissioning of new tooling for assembly and test stations

Collaborate closely with the Supply Chain and Manufacturing teams to source components and ensure design for manufacturing and assembly (DFMA) principles are implemented

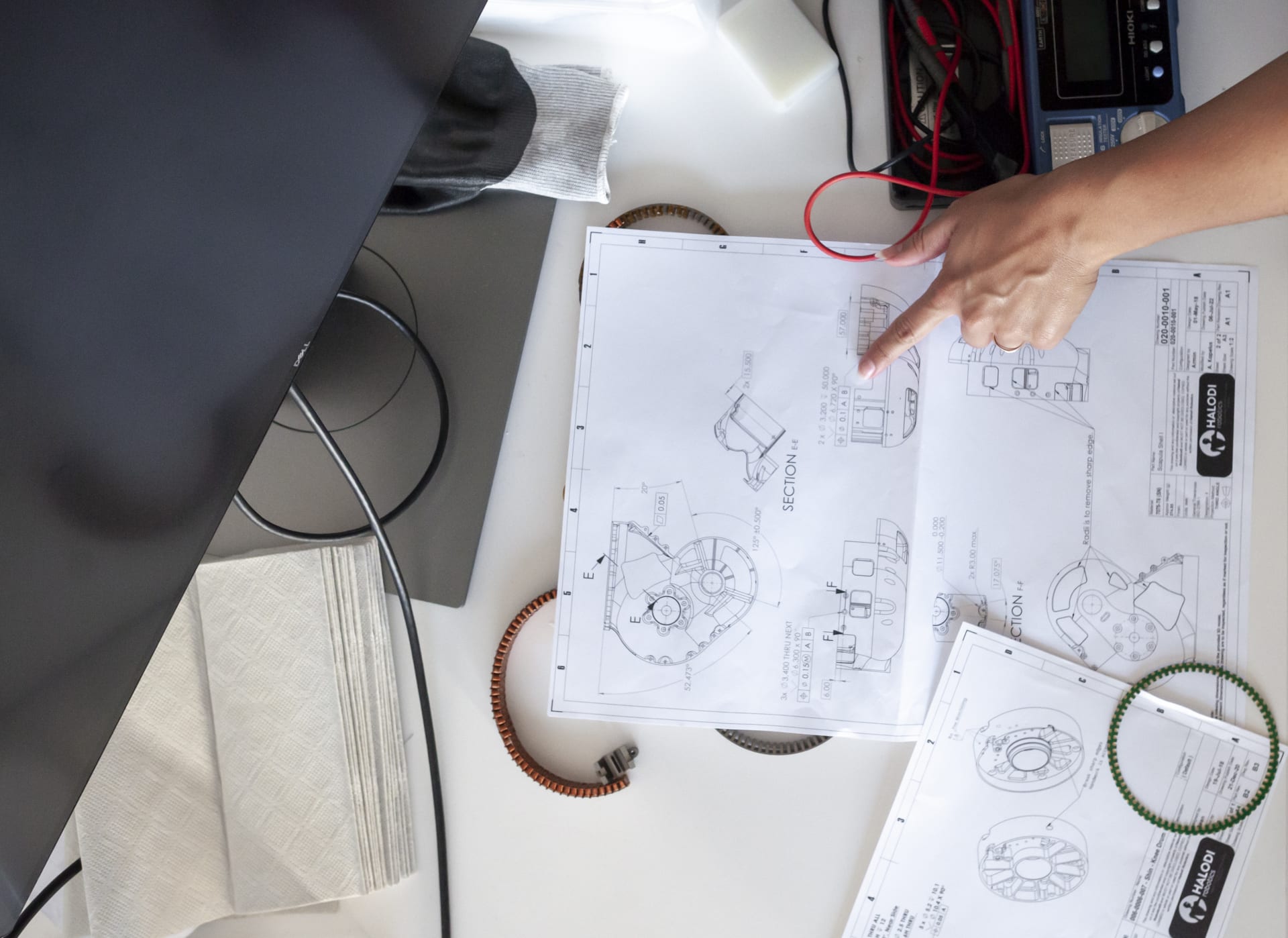

Own all tooling designs and documentation related to your role in production engineering

Within one year, you will…

Be the go-to expert for tooling (jigs, fixtures) and bespoke assembly solutions in your area of responsibility

Lead production activities, including prototype builds and serial production trials, ensuring your tooling solutions meet quality and efficiency standards

This is an opportunity to work on groundbreaking technology and make a real impact in the future of humanoid robotics.

Job requirements

Must-Haves:

Bachelor’s degree in Mechanical Engineering, Mechatronics, or Industrial Engineering

3+ years of experience in a manufacturing, testing, or design engineering role (Experience from student project teams or internships will also be considered)

Strong background in Geometric Dimensioning and Tolerancing (GD&T) with hands-on experience developing and interpreting technical drawings

Proven ability to design mechanical systems for high-volume production, ideally with an automotive or robotics focus

Experience in commissioning tooling and equipment, from testing to full-scale production, and driving projects from R&D through to production ramp-up

Demonstrated project management skills with a track record of delivering complex projects on time and within budget in a hardware or manufacturing startup

Experience with Solidworks CAD and Altium

Nice-To-Haves:

"Get-things-done" attitude

A proven ability to drive the development and implementation of manufacturing solutions in fast-paced, high-tech environments, with a focus on continuous improvement and innovation

Extensive experience with automotive manufacturing or robotics systems as a Tooling Engineer, particularly in developing solutions for technically complex electromechanical products (e.g. jigs, fixtures and other types of bespoke or off-the-shelf tooling)

Experience in high-volume production lines, including familiarity with automated assembly processes

Location

We believe the best work is done when collaborating and therefore require in-person presence in our office locations.

1X is an inclusive and equal-opportunity employer that values diversity. We consider all qualified applicants regardless of race, religion, gender, age, sexual orientation, disability, or any other protected class. If you have a disability or special need that requires accommodation, please don't hesitate to let us know during the interview process. We will do our best to accommodate your needs.

We're excited to get to know you and the prospects of having you on board!

or

All done!

Your application has been successfully submitted!

Explore Careers at 1X.

Our mission is to design Androids that work alongside people, to meet the world’s labor demands and build an abundant society.