Manufacturing Process Engineer

- On-site

- Palo Alto, California, United States

- Manufacturing and Production

Job description

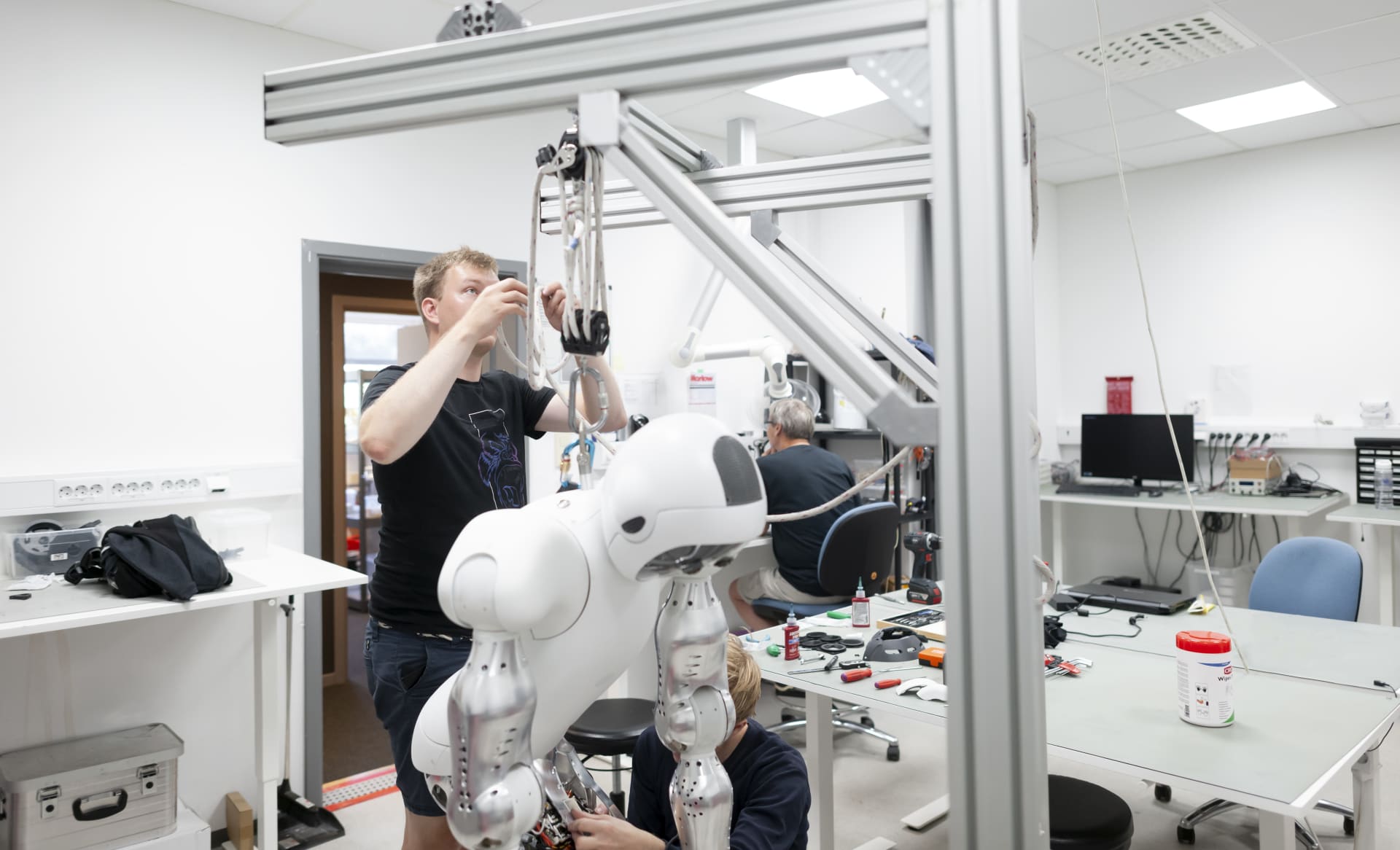

Since its founding in 2015, 1X has been at the forefront of developing advanced humanoid robots designed for household use. Our mission is to create an abundant supply of labor via safe, intelligent humanoids.

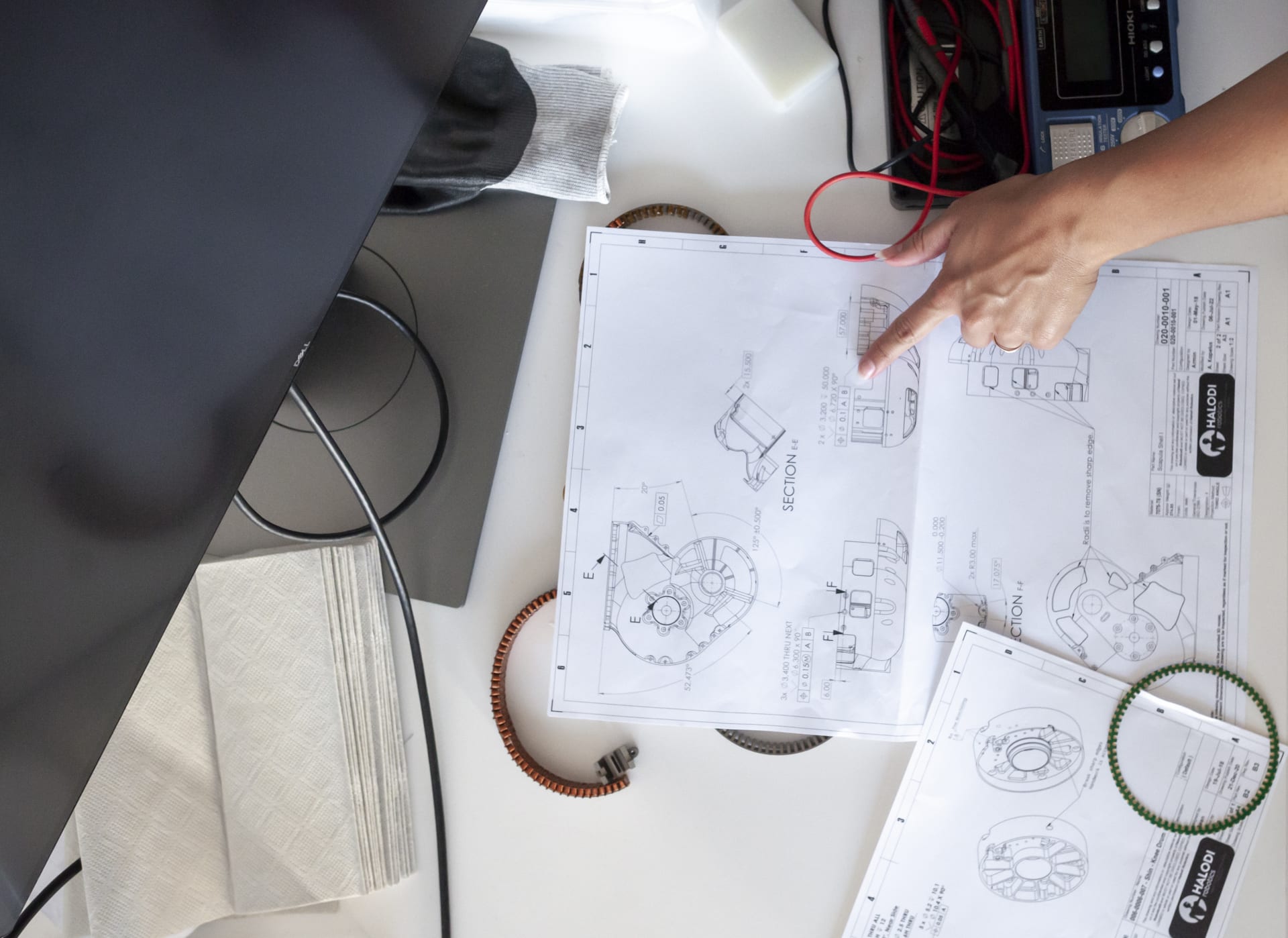

We strive for excellence in all we do, solving some of the hardest problems in robotics with the world’s most talented individuals. Every part of our robots is designed and produced in-house—from motor coils to AI—reflecting our vertically integrated approach. At 1X, you’ll own real projects, be recognized for your achievements, and rewarded based on merit.

We believe the best work is done when collaborating and therefore require in-person presence in our office locations.

As we scale from research and development to full-scale manufacturing, we are looking for a Manufacturing Process Engineer to support the scale-up of our humanoid robot production. This role is pivotal in delivering process excellence, improving quality, increasing throughput, and reducing costs using lean manufacturing principles and data-driven decision-making. The ideal candidate thrives in a fast-paced, cross-functional environment and has a strong background in process development and continuous improvement.

RESPONSIBILITIES

Develop and maintain detailed production documentation, including work instructions, process flows, and Bills of Materials (BOMs).

Lead and contribute to continuous improvement initiatives using tools like Value Stream Mapping, 5S, SMED, and OEE.

Design and implement process improvements that enhance quality, labor efficiency, cycle time, and throughput.

Analyze and improve manufacturing workflows to reduce lead time, cost, and variability.

Own and update Work Instructions (WI) and process control plans.

Collaborate with Production, Quality, R&D, and Service teams to drive process stability and improvement.

Identify and resolve manufacturing constraints with robust, scalable solutions.

Train operators and technicians on new or updated processes and standards.

Lead product and process validation efforts, including documentation and data analysis.

Support New Product Introduction (NPI) efforts during early builds, design reviews, and process definition.

Contribute to DFM activities and conduct PFMEAs to ensure robust process designs.

Specify, validate, and implement tooling, fixtures, equipment, and line layouts.

Support capital investment justifications through data-driven financial and productivity analyses.

Participate in cost reduction and value engineering initiatives, including make-vs-buy decisions and automation integration.

Generate and present performance reports and trend data to key stakeholders.

Conduct time-motion studies and use work measurement systems (e.g., MOST) to improve manpower efficiency.

Promote safety and drive CAPA efforts to resolve technical and quality issues.

Oversee pilot production projects, documenting materials, issues, and lessons learned to ensure smooth ramp-up to full production.

Job requirements

Bachelor’s degree in Mechanical, Industrial, or Manufacturing Engineering (or related field).

3+ years of experience in a process engineering or manufacturing engineering role.

Strong knowledge of lean manufacturing, continuous improvement, and process optimization.

Experience with NPI, process validation, and DFM/DFX methodologies.

Skilled in root cause analysis, corrective actions, and manufacturing analytics.

Proficiency with CAD tools, ERP/MRP systems, and manufacturing software.

Excellent communication, leadership, and cross-functional collaboration skills.

Ability to manage projects and mentor technicians or junior engineers.

Nice to have

Experience with MOST or equivalent work measurement systems.

Formal Lean/Six Sigma certification or training.

Experience in high-volume or early-stage hardware production environments.

Location Policy

We believe the best work is done when collaborating and therefore require in-person presence in our office locations.

We're excited to get to know you and the prospects of having you on board!

or

All done!

Your application has been successfully submitted!

Explore Careers at 1X.

Our mission is to design Androids that work alongside people, to meet the world’s labor demands and build an abundant society.