Manufacturing Design Engineer

- On-site

- Palo Alto, California, United States

- Manufacturing and Production

Job description

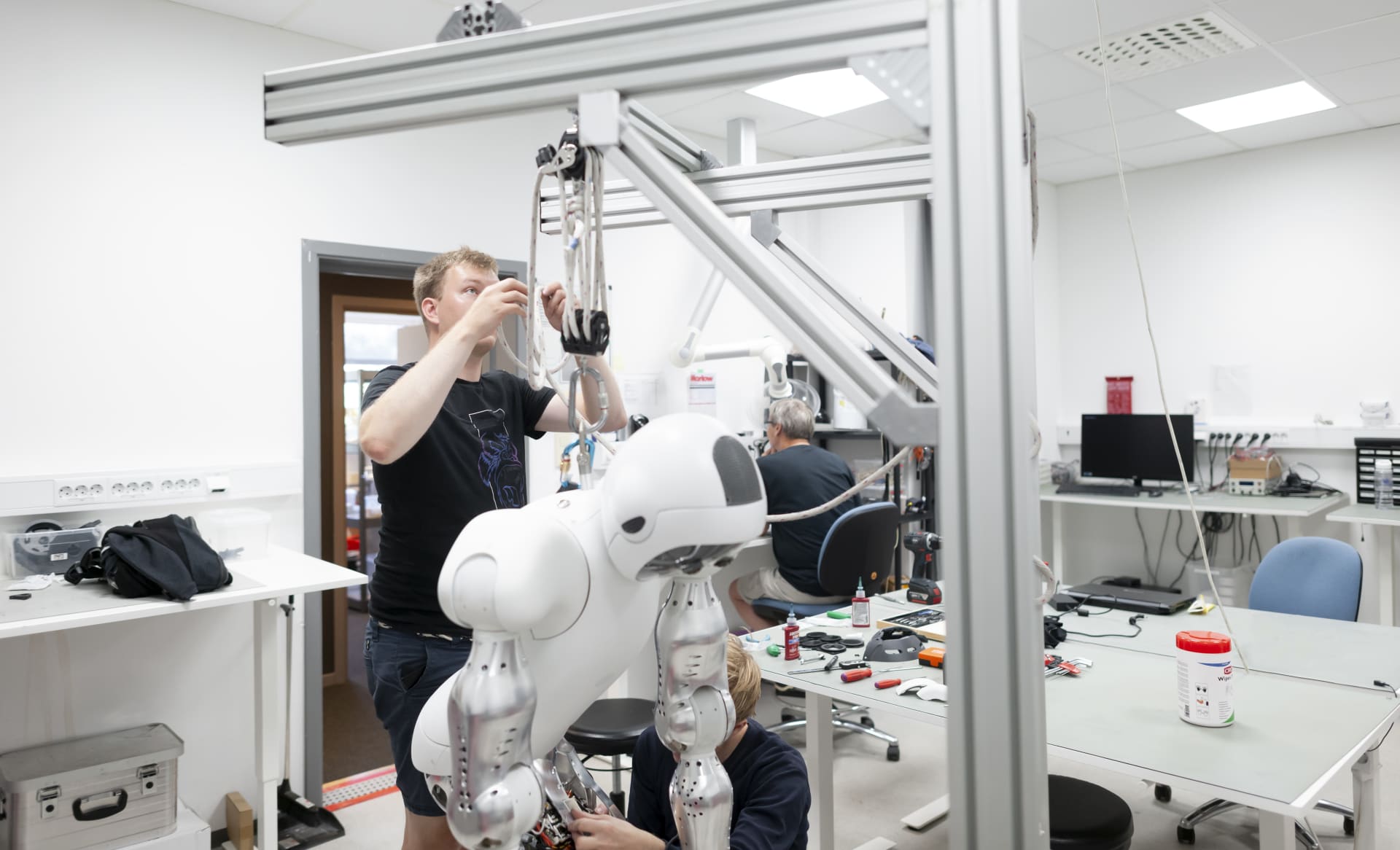

Since its founding in 2015, 1X has been at the forefront of developing advanced humanoid robots designed for household use. Our mission is to create an abundant supply of labor via safe, intelligent humanoids.

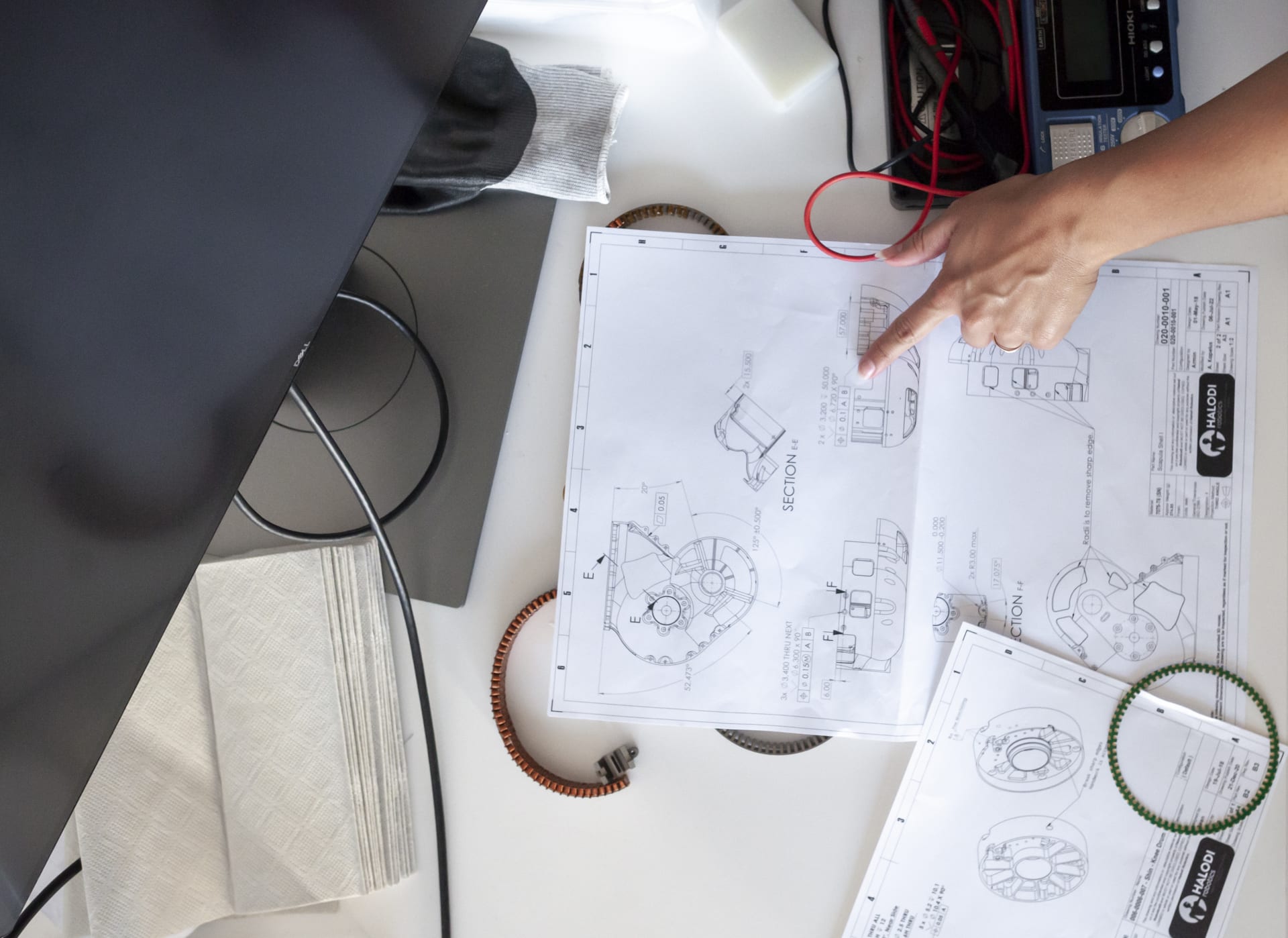

We strive for excellence in all we do, solving some of the hardest problems in robotics with the world’s most talented individuals. Every part of our robots is designed and produced in-house—from motor coils to AI—reflecting our vertically integrated approach. At 1X, you’ll own real projects, be recognized for your achievements, and rewarded based on merit.

We believe the best work is done when collaborating and therefore require in-person presence in our office locations.

As we scale from research and development to full-scale manufacturing, we are looking for a Manufacturing Design Engineer. The Manufacturing Design Engineer plays a key role at the intersection of product design and manufacturing. You’ll serve as a key contributor to Design for Excellence (DFx), ensuring our mechanical and electro-mechanical designs are optimized for manufacturability, testability, and assembly. You will work closely with Manufacturing Engineers (MEs), Manufacturing Process Engineers (MPEs) and Manufacturing Process Execution Engineers (MPEXs) to translate engineering intent into reality on the production floor.

RESPONSIBILITIES

Collaborate with mechanical, electrical, and controls design teams to ensure new and existing product designs are optimized for manufacturability (DFM), assembly (DFA), test (DFT) and cost (DFC).

Serve as the manufacturing liaison during the product design lifecycle, providing early and continuous feedback to improve manufacturing outcomes.

Lead and contribute to Design Reviews with a manufacturing lens, identifying potential issues before release to production.

Develop and validate mechanical design features, tolerances, and specifications to support repeatable and scalable assembly processes.

Drive advanced manufacturing initiatives including process development, tooling design, fixture specification, and validation.

Identify and introduce innovative manufacturing technologies that support product scalability and performance.

Define and optimize COGS (Cost of Goods Sold) targets by identifying cost drivers and delivering manufacturable design solutions.

Work closely with Manufacturing Process Engineers to co-develop fixturing, tooling, and ergonomic workstations.

Interface with Manufacturing Process Execution Engineers to validate line layouts, test equipment, and quality control processes based on design intent.

Contribute to New Product Introduction (NPI) efforts by supporting prototype builds, pilot runs, and the transition to mass production.

Support failure analysis, root cause investigations, and corrective actions related to design-for-manufacturing issues.

Document best practices and design guidelines based on lessons learned in production and field deployment.

Participate in the development of engineering change orders (ECOs) related to manufacturability enhancements.

Job requirements

Bachelor’s degree in Mechanical Engineering, Mechatronics, or related field.

6+ years of experience in a manufacturing design or product development environment.

Deep understanding of DFM/DFA/DFx, GD&T, and tolerance stack-up analysis.

Experience with high-volume product design and ramp-to-production environments

Strong knowledge with design for high volume production methods like castings, forgings, stamping and other advanced methods.

Experience working with CAD (SolidWorks, or equivalent) and PLM systems.

Familiarity with materials selection, tolerance stack-up analysis, and design validation techniques.

Demonstrated success working in cross-functional teams including design, manufacturing, quality, and test engineering.

Ability to interpret and contribute to mechanical drawings, BOMs, and technical documentation.

Strong problem-solving, communication, and collaboration skills.

Nice to have

Experience designing for automated or semi-automated assembly lines.

Experience in cost modeling, value engineering, or design-to-cost projects.

Hands-on prototyping or fabrication experience (3D printing, CNC, etc.).

Exposure to collaborative robot or electromechanical system design.

Familiarity with FMEA and other risk assessment tools.

Location Policy

We believe the best work is done when collaborating and therefore require in-person presence in our office locations.

We're excited to get to know you and the prospects of having you on board!

or

All done!

Your application has been successfully submitted!

Explore Careers at 1X.

Our mission is to design Androids that work alongside people, to meet the world’s labor demands and build an abundant society.