Manufacturing Automation Engineer

- On-site

- Palo Alto, California, United States

- Manufacturing and Production

Job description

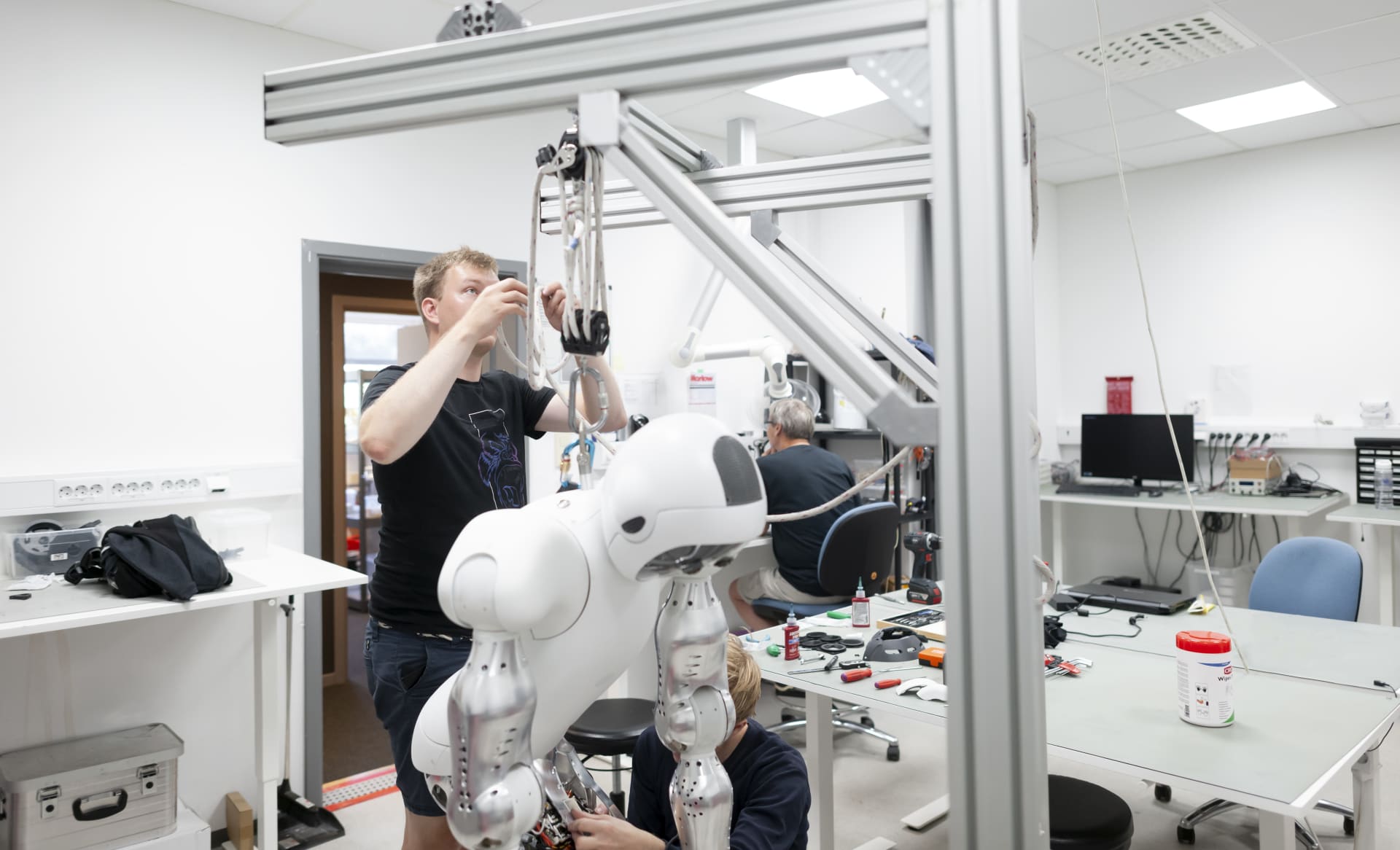

Since its founding in 2015, 1X has been at the forefront of developing advanced humanoid robots designed for household use. Our mission is to create an abundant supply of labor via safe, intelligent humanoids.

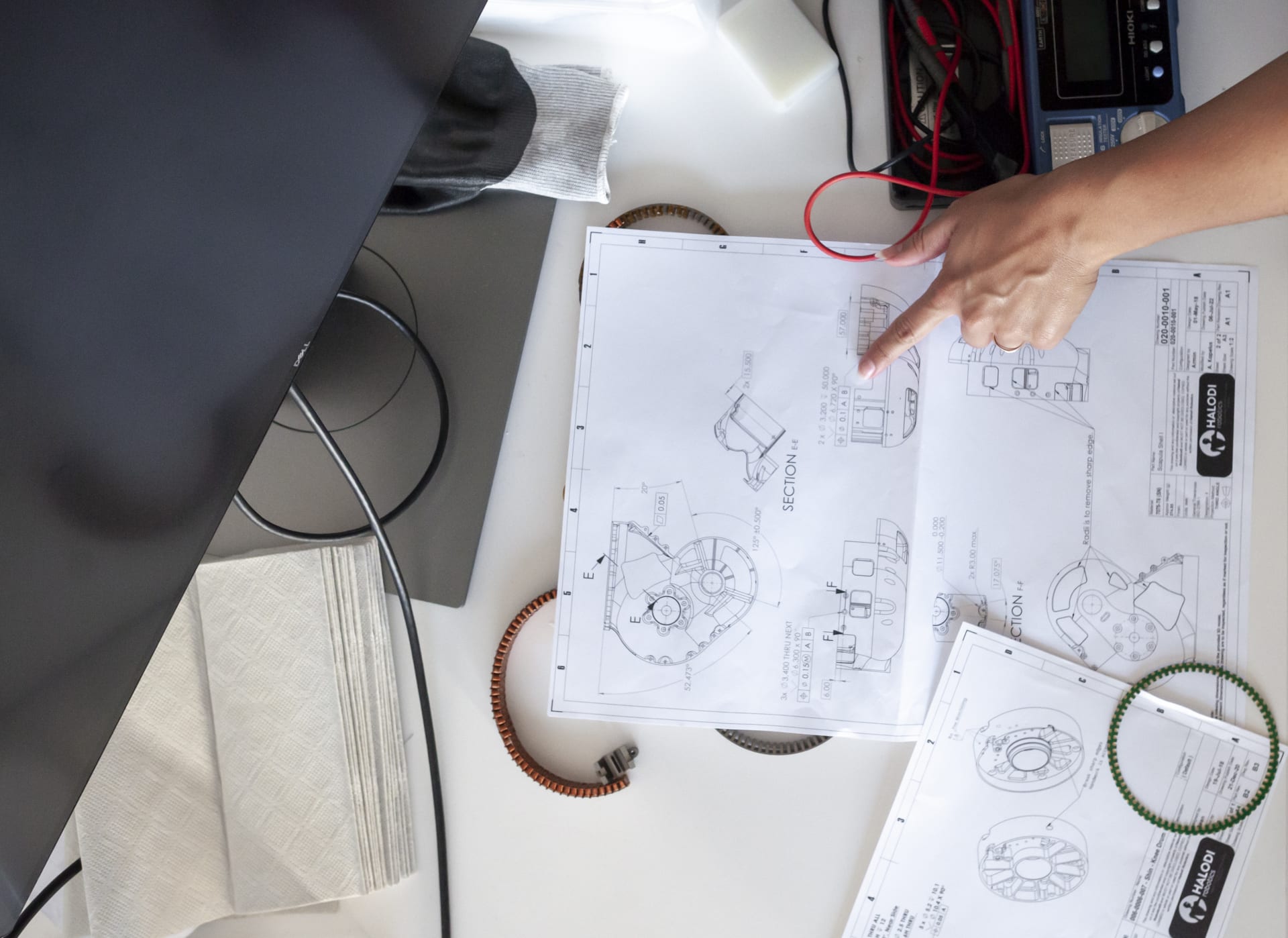

We strive for excellence in all we do, solving some of the hardest problems in robotics with the world’s most talented individuals. Every part of our robots is designed and produced in-house—from motor coils to AI—reflecting our vertically integrated approach. At 1X, you’ll own real projects, be recognized for your achievements, and rewarded based on merit.

We believe the best work is done when collaborating and therefore require in-person presence in our office locations.

As we scale from research and development to full-scale manufacturing, we are looking for a Manufacturing Automation Engineer. As a Manufacturing Automation Engineer at 1X, you’ll be at the forefront of developing custom automation solutions to transform manual and semi-manual assembly processes into scalable, efficient production systems. You’ll work cross-functionally with Manufacturing Engineers, Process Engineers, and Design teams to create intelligent, in-house equipment—integrating robotics, sensors, motion systems, and vision technology to meet production, quality, and safety goals. This is a hands-on role focused on rapid development, iteration, and deployment of novel hardware and control systems.

RESPONSIBILITIES:

Design, build, and validate bespoke automation equipment, including robotic cells, custom assembly tools, and automated test stations.

Collaborate with Manufacturing Engineers and Process Engineers to identify automation opportunities and scale manual processes.

Integrate PLCs, HMIs, actuators, vision systems, and IoT sensors into production environments.

Develop system architecture, wiring schematics, mechanical assemblies, and control software for automation systems.

Partner with Manufacturing Process Execution Engineers to ensure reliable, maintainable deployment on the production floor.

Conduct risk assessments and DFMEA for custom machines and ensure regulatory compliance where applicable.

Drive continuous improvement in cycle time, yield, and equipment uptime through automation innovation.

Create and maintain technical documentation, including schematics, BOMs, operator guides, and maintenance procedures.

Support NPI efforts by developing early automation concepts for pilot lines and scaling them for full-rate production.

Participate in capital planning and ROI analysis for automation investments.

Job requirements

Bachelor’s in Mechatronics, Mechanical Engineering, Electrical Engineering, or a related field.

8+ years experience developing industrial automation systems, with a focus on custom or high-volume equipment.

Proficient in PLC programming (e.g., Beckhoff , Siemens, Allen-Bradley), HMI development, and motion control.

Experience with CAD tools (e.g., SolidWorks), and electromechanical system design.

Skilled in robotics integration (UR, Fanuc, etc.), vision systems (Keyence, Cognex), and control loop design.

Strong understanding of manufacturing processes, DFM principles, and system safety.

Excellent hands-on prototyping, debugging, and cross-functional collaboration skills.

Nice to have

Experience in early-stage product ramp and rapid hardware iteration.

Exposure to lean manufacturing, or Six Sigma.

Prior work on collaborative robots or human-robot interface safety systems.

Ability to travel to global manufacturing sites for deployment and troubleshooting.

Location Policy

We believe the best work is done when collaborating and therefore require in-person presence in our office locations.

We're excited to get to know you and the prospects of having you on board!

or

All done!

Your application has been successfully submitted!

Explore Careers at 1X.

Our mission is to design Androids that work alongside people, to meet the world’s labor demands and build an abundant society.