Head of Production Test Engineering

- On-site

- Hayward, California, United States

- Manufacturing and Production

Job description

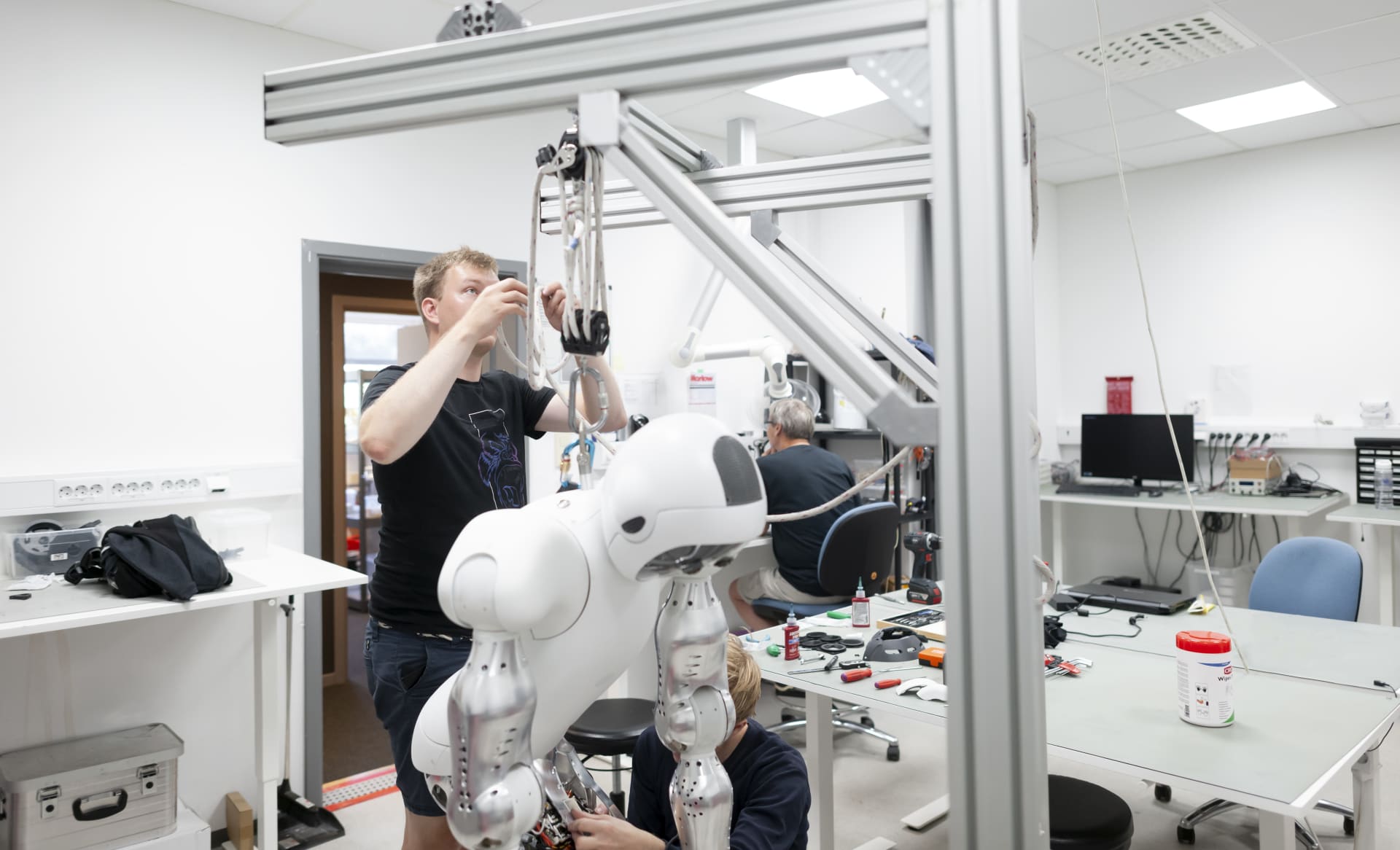

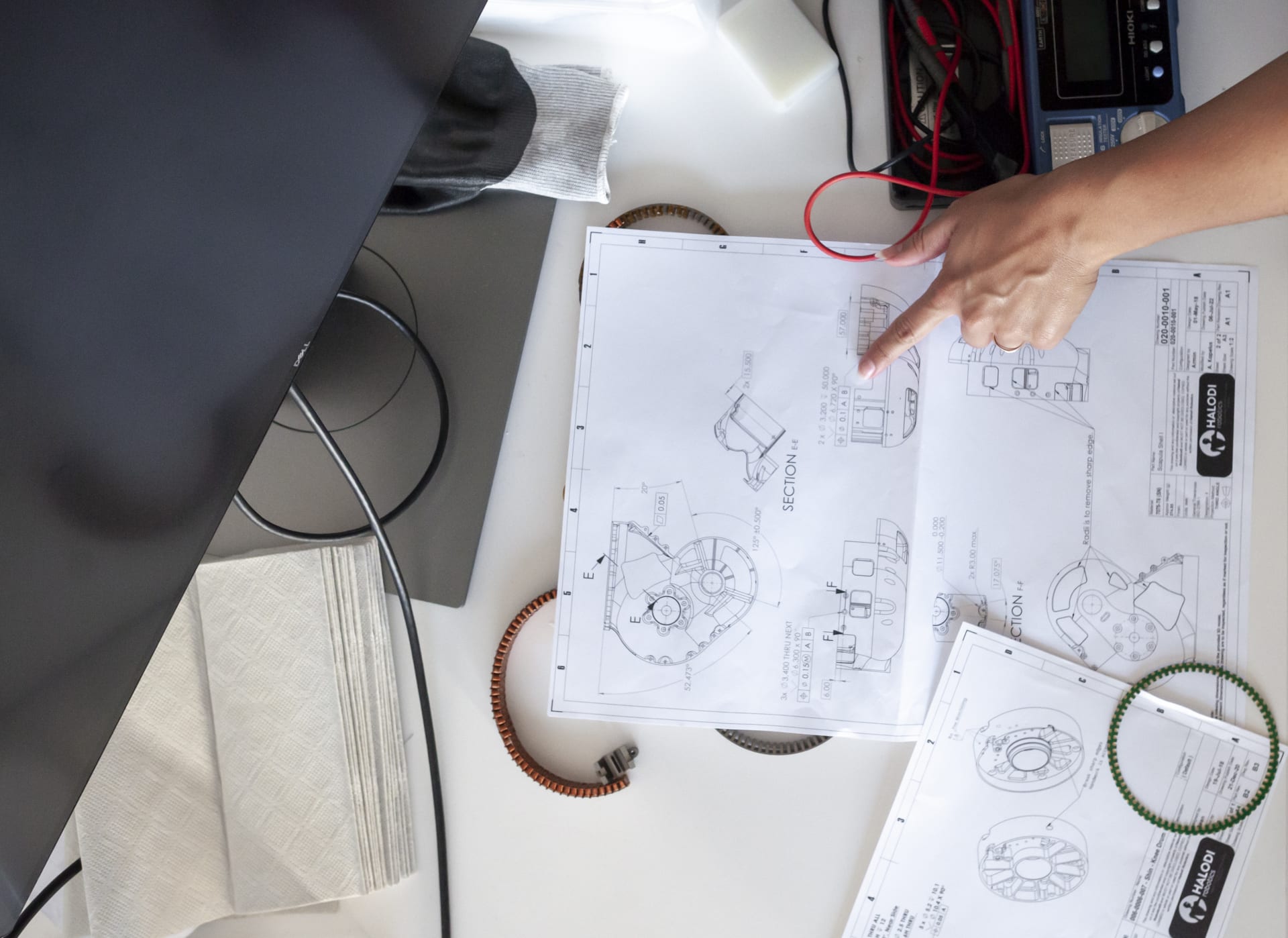

Since 2015, 1X has been pioneering the development of advanced humanoid robots for household use. Our mission is to create an abundant supply of labor via safe, intelligent humanoids. We solve complex robotics challenges with a world-class team and a vertically integrated approach, designing and producing all robot components in-house, from motor coils to AI.

As Head of Production Test Engineering, you will take a hands-on leadership role in building test infrastructure, developing hardware and software for automated testbeds, and defining in-line validation procedures. You will own the end-to-end production test strategy, ensuring that all components—PCBs, actuators, sensors, and full robot systems—are rigorously tested at scale. You will lead a team of 6–10 engineers across electronics, software, and test engineering disciplines, driving excellence in test coverage, automation, and reliability.

Responsibilities

• Develop and implement a comprehensive production test strategy for PCBs, actuators, sensors, and complete robotic subsystems.

• Design, build, and deploy automated testbeds (hardware + software) to validate electromechanical assemblies in production.

• Architect test automation frameworks, including hardware-in-the-loop (HIL), software-in-the-loop (SIL), and end-of-line (EOL) testing.

• Develop custom test fixtures for PCB and system-level validation, integrating data acquisition, power analysis, and fault detection.

• Write test automation software (Python, C++, LabVIEW, or similar) for real-time monitoring, diagnostics, and data analytics.

• Optimize test coverage and efficiency, balancing throughput, reliability, and cost in a fast-moving production environment.

• Lead debugging and root cause analysis for production failures, collaborating with manufacturing, hardware, and software teams.

• Recruit, mentor, and manage a team of 6–10 engineers, fostering technical excellence and operational efficiency.

• Define best practices and workflows for test automation, data tracking, and continuous improvement.

Job requirements

Requirements

• 6+ years of experience in production test engineering for electromechanical systems, robotics, automotive, or consumer electronics.

• Expertise in electronics testing, including power systems, signal integrity, sensor calibration, and actuator characterization.

• Proficiency in software development for test automation (Python, C++, LabVIEW, or similar).

• Hands-on experience developing hardware test fixtures, custom test racks, and automated validation tools.

• Deep understanding of manufacturing test methodologies, including functional testing, in-circuit testing (ICT), and reliability stress testing.

• Strong leadership experience, with a track record of managing teams of 6–10 engineers and scaling test infrastructure.

• Excellent debugging and problem-solving skills—able to diagnose complex system-level test failures.

• Ability to work cross-functionally with hardware, software, and manufacturing teams to ensure seamless test integration.

We encourage you to apply even if you do not meet every single qualification.

Location Policy

We believe the best work is done when collaborating and therefore require in-person presence at our office locations.

We're excited to get to know you and the prospects of having you on board!

or

All done!

Your application has been successfully submitted!

Explore Careers at 1X.

Our mission is to design Androids that work alongside people, to meet the world’s labor demands and build an abundant society.